Advanced Material Properties Measurements with Optical Metrology

ABSTRACT

15:36, Feb 24

15:19, Feb 19

1 min read

Charles-Olivier Amyot

:

June 29, 2021 7:55:37 PM EDT

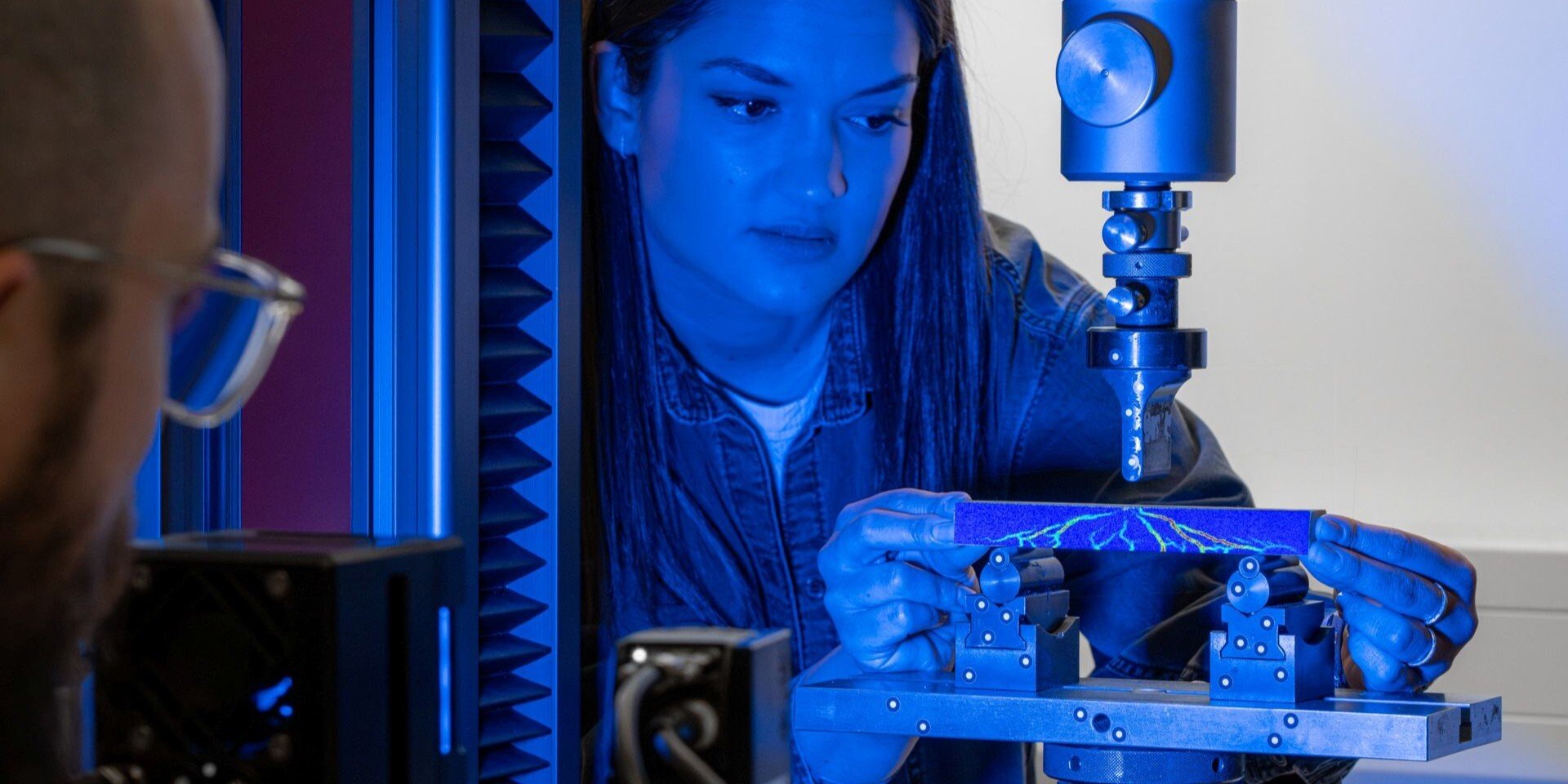

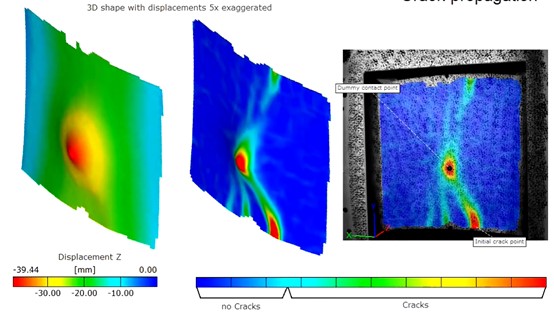

The team at FADI-AMT is world-class and their expertise using our Digital Image Correlation technology is impressive. They presented an amazing webinar last week on how to calibrate a springback model in sheet metal stamping using experimental characterization. Look at the solutions they presented to this problem through a set of experimental tools that are particularly designed for a successful calibration of springback models and how they integrated 2D and 3D digital image correlation in ways that cannot be achieved by other modes of Extensometry and strain measurements.

Prediction of Springback is a very critical topic in sheet metal stamping, not only because of the complex models needed for its prediction, but also because it is difficult to perform the experimental characterization in the first place. There are no standard mechanical testing machines that can fully address the needs of such models without compromises. On the other hand, increased use of lightweight materials (advanced high strength steels with complex microstructures and aluminium alloys with higher strengths) escalates the problems with springback prediction especially that strength-to-stiffness ratios and anisotropy levels are continuously going up.

FADI-AMT48 Brookfield Oaks Dr, Suite D |

Trilion Quality Systems651, Park Avenue |

ABSTRACT

ABSTRACT

1 min read

If you missed our Webinar: Full-Field Optical Strain Measurement Systems for Materials and Structures Certification, we have you covered. Just click...