1 min read

Verification of 3D Image Correlation Using Digital High-Speed Cameras

Ben Eisdorfer

:

June 22, 2023 11:35:54 AM EDT

ABSTRACT

Performance Verification of 3D Image

Correlation Using Digital High-Speed Cameras

T. Schmidt, J. Tyson, Trilion Quality Systems, 200 Barr Harbor Dr. Suite 400, West Conshohocken, PA 19428

D.M. Revilock, Jr., S. Padula II, J.M. Pereira, M. Melis, NASA Glenn, 21000 Brookpark Rd, Cleveland, OH 44135

K. Lyle, NASA Langley Research Center, 12 West Bush Road, MS 495, Hampton, VA 23681

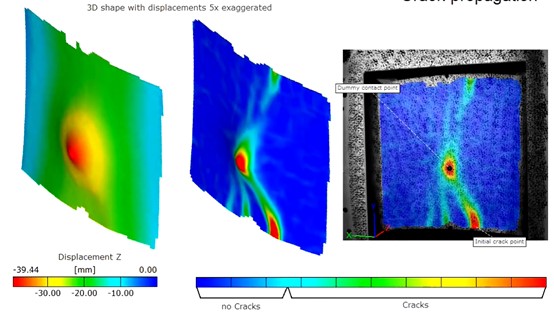

3D image correlation photogrammetry using Phantom v7 digital high-speed cameras is being used extensively to verify and iterate finite element models of ballistic impact events for the NASA Return to Flight program. In order to ensure the accuracy of the dynamic displacement and strain data measured with the 3D image correlation system, a series of performance tests was conducted in both field and laboratory conditions, with data acquisition rates from 10,000-27,000 frames per second. Rigid body panel translation results conducted in-situ on a test range matched a calibrated micrometer within 1.09% for 0.1” increments from 0.1 to 1.0 inches, with much greater accuracy for most increments. Dynamic displacements from a bend and release test in a laboratory closely matched those from a laser interferometer, with a worst-case error of 1.27%, and strains from the same test closely matched both strain gauges and calculated values. In addition, dynamic strains reported during critical Return to Flight Orbiter wing leading edge panel impact tests were repeatedly found to match data from strain gauges within the field of view. 3D image correlation using digital high-speed cameras has been shown to be an invaluable tool, now in everyday use for critical ballistic impact investigations. The technique is also broadly applicable for air blast deformation measurements, crash testing, drop testing, high strain rate testing, and other dynamic phenomena.

access the whole paper!

Optimizing Composite Overwrapped Pressure Vessels with DIC Testing

In the world of aerospace engineering and material science, the development of Composite Overwrapped Pressure Vessels (COPVs) marked a significant...

1 min read

WEBINAR: How to Automate Material Testing and Batch Process Data

If you missed our Webinar, How to Automate Material Testing and Batch Process Data, we have you covered. Just click the button below, fill out the...