Webinar: ZEISS ARAMIS 1, Your Entry Point into 3D Optical Testing

If you missed our Webinar: Introducing ZEISS ARAMIS 1, Your Entry Point into 3D Optical Testing, we have you covered. Simply click the button below, complete the attached form, and follow the link to start watching the webinar. Here is a short description of what is covered in the webinar:

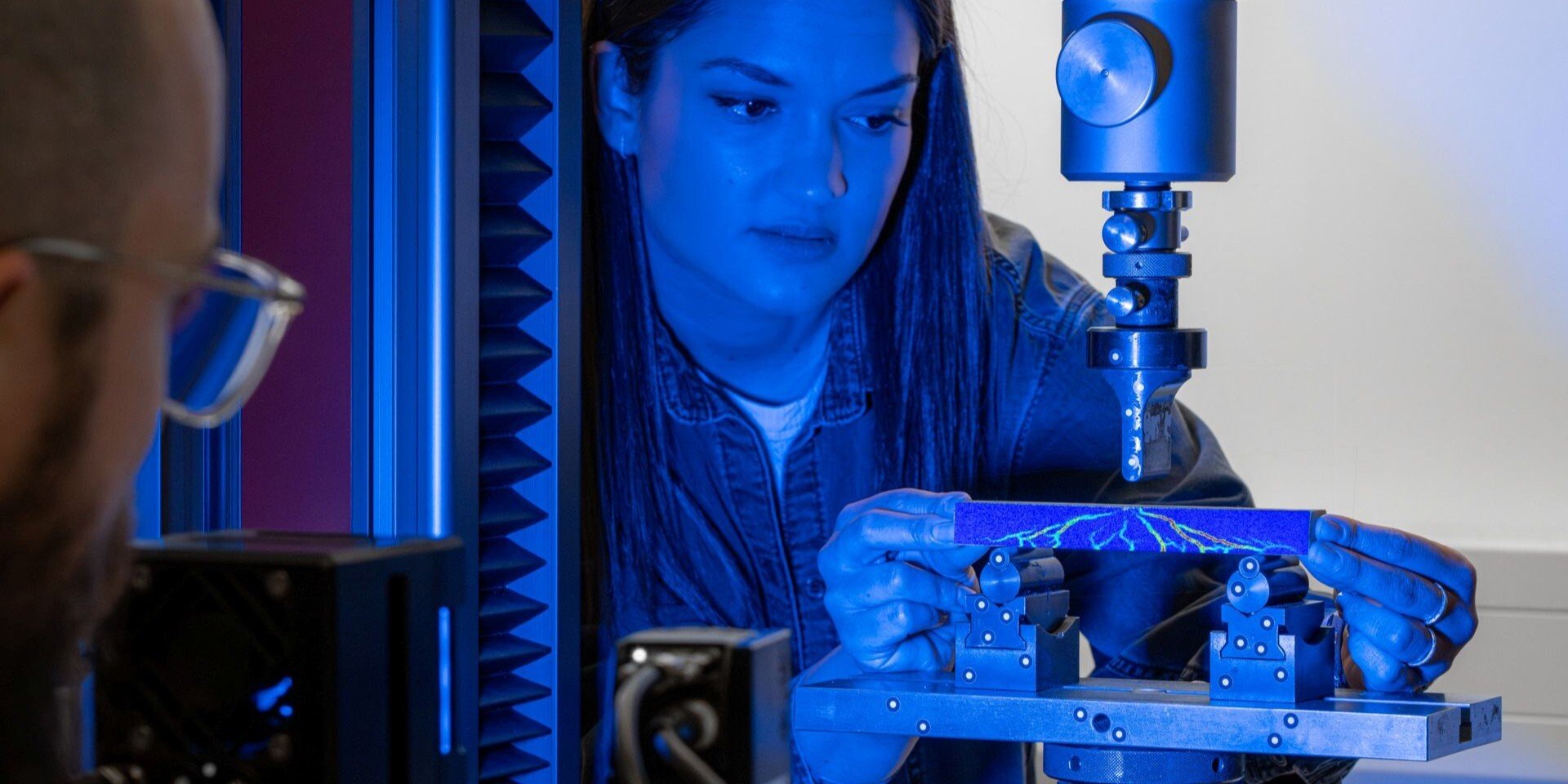

We’re thrilled to unveil the newest member of the ARAMIS Optical Testing lineup: the ZEISS ARAMIS 1, designed as the ideal entry point into the world of 3D optical measurement and Digital Image Correlation (DIC).

What You Will Learn:

- Get a first look at ZEISS ARAMIS 1 and discover how it’s bringing powerful, non-contact, full-field measurement to more labs and industries.

- Understand how the system delivers precise 3D strain, deformation, and displacement data across a wide range of testing applications — from tensile and bending tests to dynamic motion analysis.

- See how ARAMIS 1 integrates seamlessly with ZEISS CORRELATE software for intuitive, detailed analysis.

- Watch a live demo of ZEISS ARAMIS 1 in action and experience firsthand how it captures and analyzes data with ease.

- Learn how ARAMIS 1 sets the stage for scalable, future-ready optical testing, making it the perfect starting point for companies looking to elevate their measurement capabilities.

Whether you’re new to optical testing or looking to expand your lab’s potential, this 45-minute product reveal and demo will show you why ZEISS ARAMIS 1 is a game changer.