How we saved $2M on a 2-month project using optical sensors

The use of an optical measurement system for structural proof testing, which measures deflection and strain data, can save valuable schedule time. In...

14:55, Apr 30

14:23, Apr 25

ABSTRACT

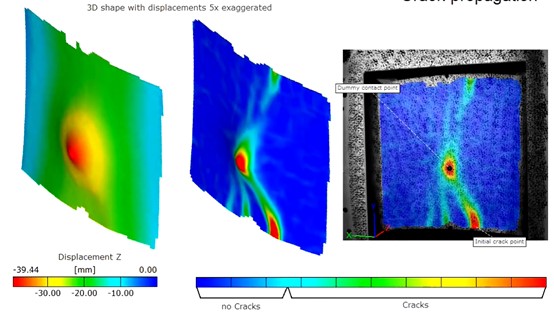

The Factory of the Future greatly uses optical measurement systems throughout the design, testing, and manufacturing of next-generation materials, structures, and products. Optical measurements open advanced analysis capabilities for structural testing and understanding the complexities of advanced designs. Digital Image Correlation (DIC) and Photogrammetry are critical measurement methods for automotive materials and structures because of their ability to measure the entire structure holistically, simply, and rapidly. This system measures displacements better than Draw-wire, LVDTs, and clip gauges and measures strain better than strain gages. This technology is applicable to performance studies in test lab measurements to on-vehicle field testing. The work will look at NVH, deformations, and strains, on traditional vehicle measurements, from engines, body components, and exhaust systems. This paper will discuss these advanced capabilities for the automotive industry and beyond.

The use of an optical measurement system for structural proof testing, which measures deflection and strain data, can save valuable schedule time. In...

ABSTRACT

Throughout our history, Trilion Quality Systems has helped customers in the aerospace industry to obtain the best possible data for their testing...