2 min read

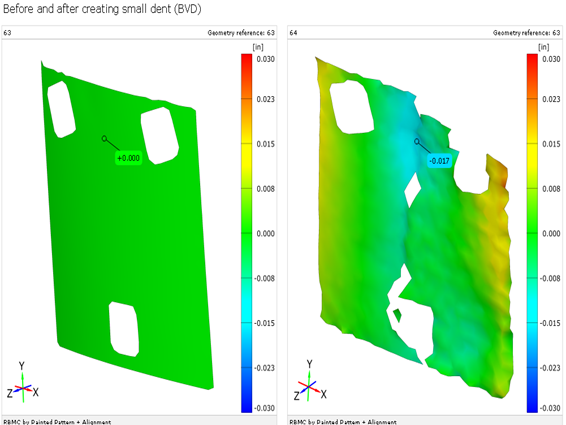

Using DIC with Vinyl Stencils for Barely Visible Damage Assessment

Ben Eisdorfer

:

May 14, 2024 4:37:14 PM EDT

In the realm of aerospace engineering and maintenance, ensuring the integrity of aircraft surfaces is paramount. Even the slightest damage, often imperceptible to the naked eye, can compromise safety and performance. To address this challenge, digital image correlation (DIC) coupled with vinyl stencils emerges as a powerful tool for Barely Visible Damage (BVD) assessment. Let's delve into the objectives of this innovative approach:

Objective 1: Quantify As-Built Surfaces Before and After Shipments

Before an aircraft is shipped from manufacturing, meticulous documentation of its pristine surfaces is imperative. By employing DIC with vinyl stencils, engineers can precisely quantify the as-built surfaces, capturing every intricate detail. This baseline data serves as a reference point for comparison post-shipment, enabling swift detection of any deviations or damages incurred during transit.

Objective 2: Measure Surfaces Upon Arrival to Detect BVD

Upon the aircraft's arrival, the meticulous scrutiny begins. Leveraging DIC technology in conjunction with vinyl stencils allows engineers to meticulously measure surfaces, even those that appear unblemished to the human eye. By detecting barely visible damages promptly, corrective measures can be swiftly implemented, safeguarding against potential safety hazards and preventing minor issues from escalating into major concerns.

Objective 3: Document Changes in Surface Shape Over Time

Aircraft undergo wear and tear over their operational lifespan. By consistently employing DIC with vinyl stencils at regular intervals, engineers can document subtle changes in the shape of surfaces. This longitudinal data provides valuable insights into the structural health of the aircraft, facilitating proactive maintenance interventions and extending its operational longevity.

Objective 4: Check for Strains in Critical Load Areas

Certain areas of an aircraft are subjected to higher stresses during operation. Through DIC with vinyl stencils, engineers can pinpoint and analyze strains in critical load areas with exceptional precision. Identifying potential weak points enables proactive reinforcement measures, ensuring the aircraft's structural integrity and minimizing the risk of catastrophic failures.

Methodology: Pioneering BVD Assessment with DIC and Vinyl Stencils

Achieving the objectives outlined for Barely Visible Damage (BVD) assessment requires a meticulous methodology that seamlessly integrates digital image correlation (DIC) with vinyl stencils. Here's how we do it:

1. Surface Patterning with Perforated Vinyl and CNC Cut Coded Markers

The process commences with meticulously patterning the aircraft surfaces using perforated vinyl sheets. These sheets are tailored to conform precisely to the contours of the surfaces under scrutiny. Concurrently, CNC (Computer Numerical Control) technology is employed to intricately cut coded markers onto the vinyl sheets. These markers serve as fiducial points, facilitating precise alignment and correlation of surface data.

2. Utilization of Coded Markers for Surface Stitching

Each perforated vinyl sheet, adorned with coded markers, serves as a discrete surface patch. During the DIC imaging process, these patches are captured individually. However, the magic unfolds during post-processing, where the coded markers act as stitching points. By correlating the markers across adjacent patches, a cohesive, high-fidelity representation of the entire surface is reconstructed with remarkable accuracy.

3. Alignment of Surface Patches to the CAD Model

To ensure data integrity and fidelity to the aircraft's original design, each surface patch is automatically aligned to its corresponding CAD (Computer-Aided Design) model using the Zeiss Inspect Correlate software. This alignment process serves as a crucial calibration step, enabling accurate comparison between the digital reconstruction and the theoretical model. Any deviations detected during this alignment phase serve as early indicators of potential damage or deformation.

In conclusion, the integration of digital image correlation with vinyl stencils revolutionizes BVD assessment in the aerospace industry. By achieving the outlined objectives, engineers can proactively safeguard aircraft integrity, enhance safety standards, and prolong operational efficiency. This innovative approach exemplifies the marriage of technology and meticulous engineering, underscoring the commitment to excellence in aviation maintenance practices.

Optimizing Composite Overwrapped Pressure Vessels with DIC Testing

In the world of aerospace engineering and material science, the development of Composite Overwrapped Pressure Vessels (COPVs) marked a significant...

How we saved $2M on a 2-month project using optical sensors

The use of an optical measurement system for structural proof testing, which measures deflection and strain data, can save valuable schedule time. In...