Advanced Material Properties Measurements with Optical Metrology

ABSTRACT

20:27, Dec 15

19:22, Dec 11

1 min read

Ben Eisdorfer

:

April 24, 2024 2:19:15 PM EDT

ABSTRACT

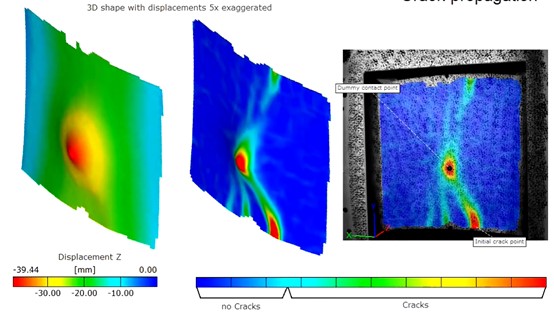

3D Digital Image Correlation (DIC) provides the ability to measure non-contact 3D coordinates, displacements, and strains of materials and structures. Although widely accepted in mechanical engineering and materials engineering, this tool has yet to prove its capability within the biomechanics industry with soft tissues, bones, and most medical-specific materials. Known for its unique capability to be used for rapid full-field measurements from material characterization to full component testing, providing the equivalent of the results of over 10,000 contiguous strain gauges or displacement sensors, this technique is now recognized and certified (NIST, Boeing...) as equivalent to standard mechanical testing tools in the aerospace and automotive industries. 3D DIC is used across industries for improving the quality and the accuracy of the data collected to best understand mechanical behaviors of components or validate FEA models. This work focuses on the integration of the DIC technology with load frames such as Instron, MTS, and Zwick for simple coupon testing of soft tissues, implants, and prostheses. It was shown that DIC could, in fact, provide a more flexible measurement platform with capabilities for any coupon size, very small to large strains with a single instrument, as well as multi-axial data in every direction for each and every one of the biomechanics applications evaluated.

ABSTRACT

ABSTRACT

{% video_player "embed_player" overrideable=False, type='hsvideo2', hide_playlist=True, viral_sharing=False, embed_button=False, autoplay=True,...