Doing More with Less

In the face of an economically turbulent future, many companies have turned to operational cuts for savings. This, compounded with public failures of...

15:19, Feb 19

20:27, Dec 15

One of the challenges America faces is a growing perception that it is difficult to build innovative, durable products that people interact with. One only needs to look around at automotive recalls, infrastructure failures, or aerospace mishaps to understand the importance of good testing and manufacturing processes. Digital Image Correlation (DIC) is an essential tool to improve testing and restore public faith in manufacturing.

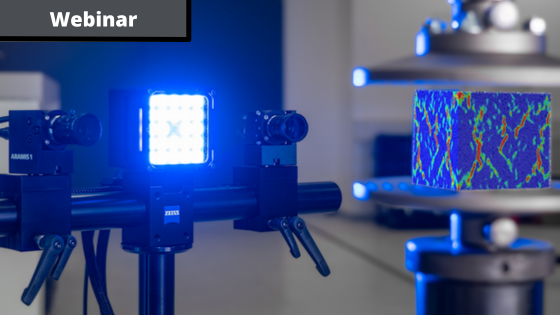

What is DIC? Digital Image Correlation is a non-contact optical method that can measure strain and displacement of an object. By capturing a series of images before, during, and after loading and analyzing the changes of the object, DIC provides detailed quantitative data about the object in various conditions.

Three Ways DIC Improves Processes

R&D: DIC drives down the cost of testing by reducing capital, equipment, and time requirements, which allows organizations to improve modeling by feeding in real-world results. Since DIC tools such as ARAMIS are material agnostic, they can be used throughout the R&D process on a variety of applications, ranging from strain to vibration and from concrete crack propagation to liquids.

Manufacturing: The importance of accurate and timely production cannot be overstated. Optical Technology (including DIC) can improve everything from aircraft fuselage precision guided assembly to sheet metal stamping. The same companies we’ve helped in R&D have turned to us for help reducing their assembly time from days to hours. Less time spent on each thing built is critical for large organizations. Robotics are also helping to accelerate the pace of manufacturing and DIC is essential to ensure that robotic movements are being tracked and performing as expected.

QA: Tools such as in-situ layup defect detection, structural health monitoring, and AR to compare to models are essential to teams using Industry 4.0 techniques. As fleets of autonomous drones take to the skies and self-driving cars take to the roads, inspection of these robotics during routine maintenance is essential. Optical Metrology inspections can also replace time-consuming manual inspections, which require more operator involvement and can lead to missing critical things if not repeated properly. QA extends throughout the life of a product, and our tools lengthen that life. Public failures are a reputational risk to organizations and a risk to public safety. Therefore, the importance of the best QA methods cannot be overstated.

We have helped many labs throughout the various stages above. Contact us to find out why most companies choose us for repeated investments after they see the power of Optical Metrology and DIC specifically!

In the face of an economically turbulent future, many companies have turned to operational cuts for savings. This, compounded with public failures of...

1 min read

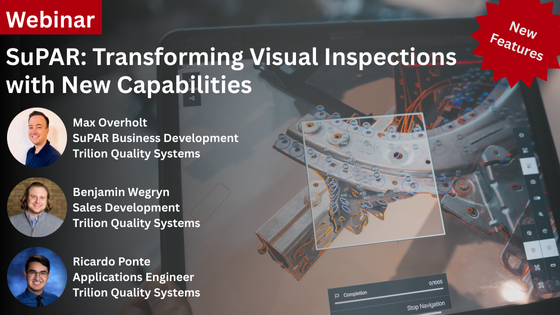

If you missed our Webinar: Introducing ZEISS ARAMIS 1, Your Entry Point into 3D Optical Testing, we have you covered. Simply click the button below,...

At Trilion Quality Systems, we recognize the pivotal role the International Digital Image Correlation Society (iDICs) plays in advancing the field of