Doing More with Less

In the face of an economically turbulent future, many companies have turned to operational cuts for savings. This, compounded with public failures of...

20:27, Dec 15

19:22, Dec 11

1 min read

Ben Eisdorfer

:

June 25, 2021 3:07:21 PM EDT

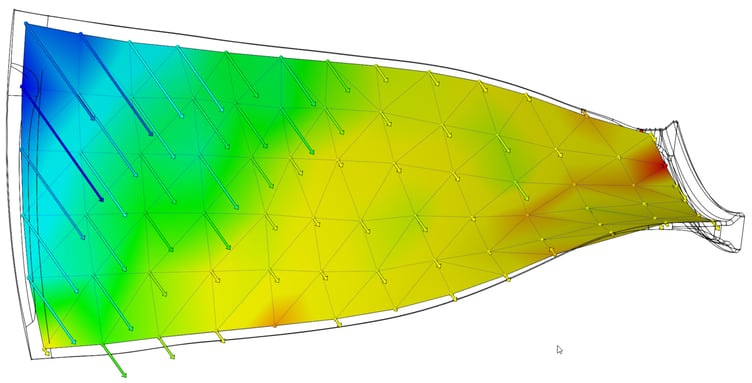

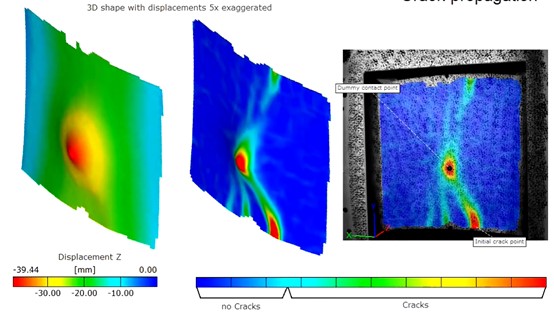

Vibration analysis requires the acquisition of test data. Historically, accelerometers have been used to measure the frequency response of structures at a select number of points. Laser vibrometers and laser scanning vibrometers are an alternative, providing a non-contact measurement. However, the measurement is long, fastidious, and not synchronous. The ARAMIS High-Speed Systems, coupled with our vibration analysis tool or third party software offer an instant improvement on the acquisition time and the quality of the data.

Vibration analysis is a key part of product development. R&D groups combine complete FEA simulation with lab testing to provide key information to the product design. Vibration testing is used in NVH reliability and operational assembly testing to validate the models, improve comfort and usability, evaluate the impact of operational and extreme working environments, and troubleshoot design issues in real-life conditions. For accurate vibration measurements, labs need:

The ARAMIS system is a non-contact sensor that measures displacements and strains on the whole surface of components. Equipped with a state-of-the-art vibration analysis module, ARAMIS can be used as a replacement for traditional vibration sensors like accelerometers or laser vibrometers. It uniquely captures synchronous and multi-point measurements and allows vibration engineers to quickly perform complete acquisition and analysis.

In the face of an economically turbulent future, many companies have turned to operational cuts for savings. This, compounded with public failures of...

ABSTRACT