1 min read

How ARAMIS stacks up against Extensometers

Measuring Strain in Materials Testing Materials testing is critical to input simulation models with the correct information. Engineers have been...

15:36, Feb 24

15:19, Feb 19

1 min read

Ben Eisdorfer

:

June 25, 2021 2:59:55 PM EDT

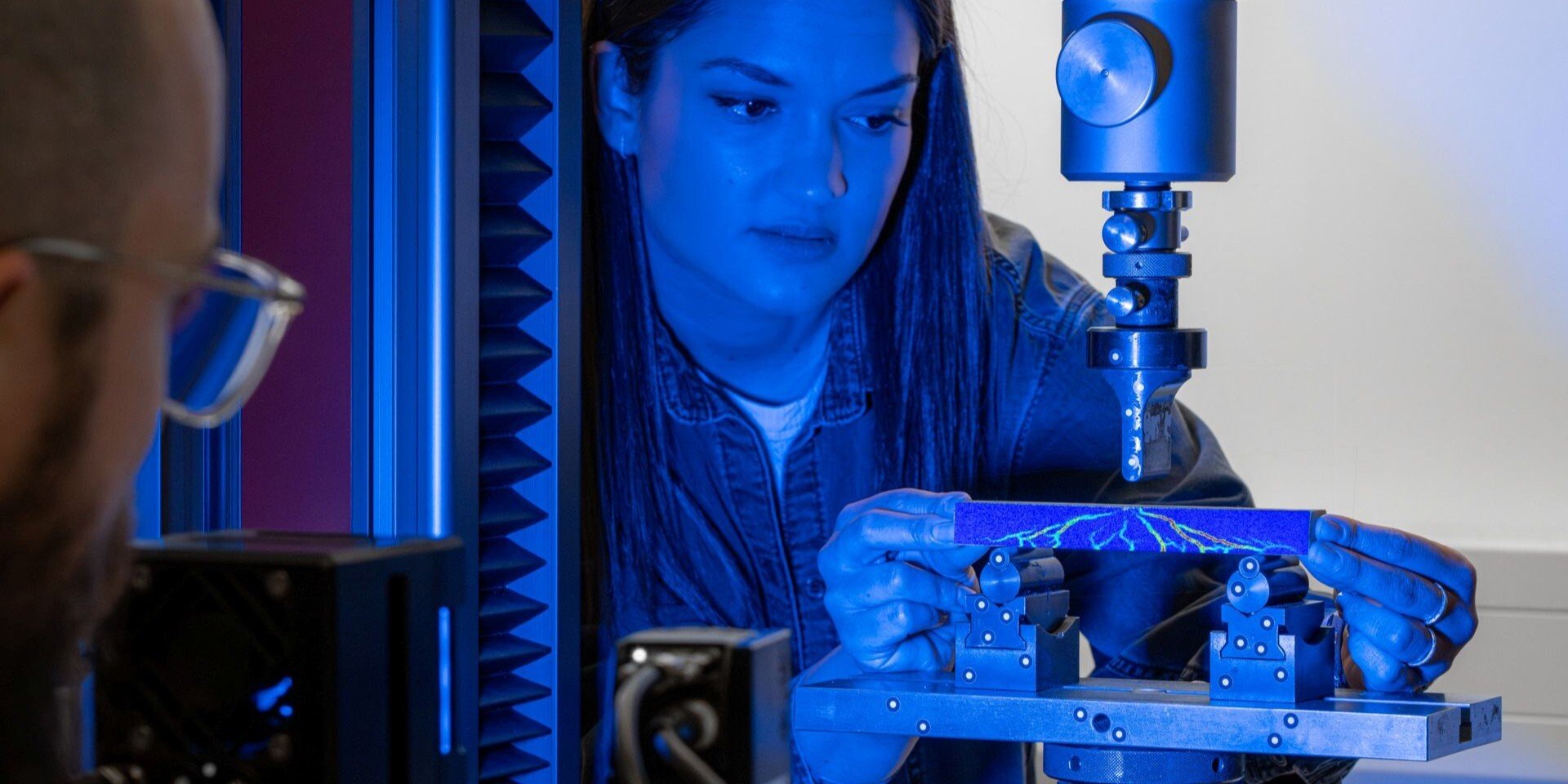

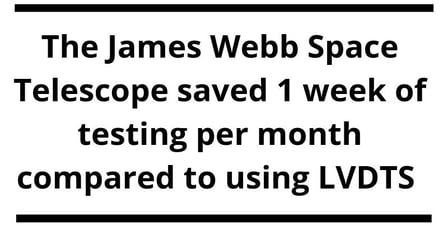

Optical metrology analyzes the mechanical properties and behavior of all kinds of materials in various test scenarios. GOM's ARAMIS systems can be integrated into existing test environments, test benches, and testing machines. The non-contact sensors measure full-field 3D strain and deformation of soft and rigid materials under mechanical or thermal load. Thus, conventional extensometers and strain gauges can easily be replaced by GOM's real-time 3D surface deformation analysis systems.

The ARAMIS system, mounted on a material testing machine, offers the ability to quickly calculate all material properties according to common ASTM and ISO standards.

The ARAMIS Kiosk Mode offers a simplified interface for test machine operators to easily collect and analyze the data according to common standards. This automated process reduces test lead time and operator variability.

1 min read

Measuring Strain in Materials Testing Materials testing is critical to input simulation models with the correct information. Engineers have been...

ABSTRACT

1 min read

If you missed our Webinar: Next-Gen Digital Material Testing: ASTM-Certified Precision, we have you covered. Simply click the button below, complete...