Using Digital Image Correlation for Jet Aircraft Engine testing

Throughout our history, Trilion Quality Systems has helped customers in the aerospace industry to obtain the best possible data for their testing...

20:27, Dec 15

19:22, Dec 11

2 min read

Ben Eisdorfer

:

December 15, 2025 3:27:35 PM EST

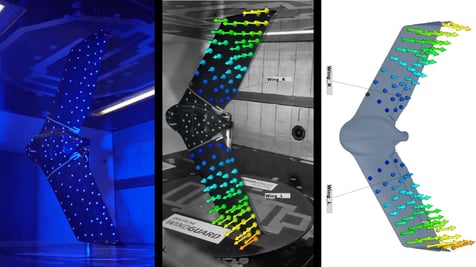

Validating Drone Performance in Wind Using Digital Image Correlation

As drones are deployed into more demanding environments, understanding how they perform in real-world wind conditions has become essential. From infrastructure inspection to defense and aerospace applications, unmanned aerial vehicles (UAVs) must maintain structural integrity, stability, and accuracy while exposed to gusts, turbulence, and changing airflow.

To validate performance before flight, engineers increasingly rely on wind tunnel testing combined with Digital Image Correlation (DIC). This approach delivers full-field insight into wind deflection and vibration testing, enabling teams to measure how a drone truly responds under aerodynamic load.

At Trilion Quality Systems, we support UAV development with advanced testing solutions that pair the ARAMIS Optical Strain System, high-speed testing, and controlled wind tunnel environments to provide accurate, actionable data.

Why Wind Testing Is Critical for UAV Design

Wind introduces complex forces that affect more than just flight stability. Even minor structural deflections can influence:

While flight testing and simulation are valuable, they don’t always reveal how structures deform under controlled, repeatable wind conditions. Wind tunnel testing allows engineers to isolate aerodynamic effects while precisely controlling airflow speed, direction, and turbulence.

To fully understand these effects, structural behavior must be measured, not assumed.

Digital Image Correlation for Full-Field Measurement

Digital Image Correlation is a non-contact optical measurement technique that captures full-field displacement and strain across an entire structure. By tracking a stochastic speckle pattern with stereo cameras, DIC provides highly detailed deformation data without influencing the test setup.

When used for wind deflection and vibration testing, Digital Image Correlation allows engineers to:

Unlike strain gauges or point-based sensors, DIC shows what is happening across the entire drone, making it ideal for complex geometries and lightweight structures.

ARAMIS Optical Strain System in the Wind Tunnel

The ARAMIS Optical Strain System is purpose-built for advanced structural testing, including aerodynamic applications. Its non-contact nature makes it especially effective for wind tunnel environments where airflow must remain undisturbed.

In UAV testing, ARAMIS enables engineers to evaluate:

Because ARAMIS delivers full-field strain and displacement data, engineers gain a deeper understanding of how wind loads affect overall performance not just isolated locations.

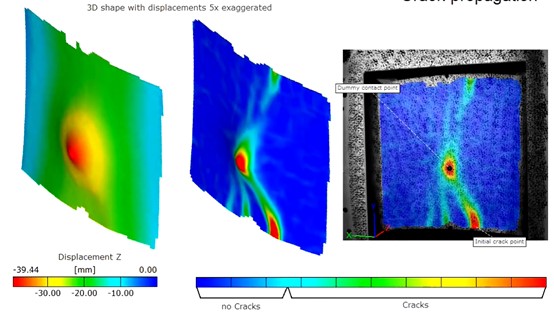

High-Speed Testing for Dynamic Wind Effects

Wind loading is rarely static. Turbulence, gusts, and rotating propellers introduce rapid, time-dependent behavior that traditional measurement methods struggle to capture.

By combining high-speed cameras with the ARAMIS Optical Strain System, engineers can perform high-speed testing to analyze dynamic deformation and vibration in real time. This approach makes it possible to:

High-speed Digital Image Correlation is especially valuable for drones operating in variable or harsh wind environments, where dynamic effects dominate performance.

Turning Test Data into Design Confidence

One of the greatest advantages of combining wind tunnel testing with Digital Image Correlation is the ability to validate simulation models. Full-field data from ARAMIS can be directly compared to finite element model (FEM).

This allows engineering teams to:

The result is faster development cycles and increased confidence that the drone will perform reliably outside the lab.

Bringing Real-World Wind Conditions into the Lab

At Trilion Quality Systems, we help organizations move beyond assumptions by delivering advanced testing solutions for UAV development. By combining Digital Image Correlation, the ARAMIS Optical Strain System, high-speed testing, and controlled wind tunnel environments, we provide the full-field insight needed to validate drone performance under real-world wind conditions.

When it comes to wind deflection and vibration testing, seeing the full picture makes all the difference.

Throughout our history, Trilion Quality Systems has helped customers in the aerospace industry to obtain the best possible data for their testing...

ABSTRACT

In the battery industry, precise measurement is critical for ensuring high-quality products that meet strict specifications. Traditional measurement...