2 min read

Using Digital Image Correlation for Jet Aircraft Engine testing

Walter Schnapp : July 9, 2024 3:39:33 PM EDT

Throughout our history, Trilion Quality Systems has helped customers in the aerospace industry to obtain the best possible data for their testing scenarios, one of which is the testing of modern jet aircraft engines. Digital Image Correlation (DIC) is one of the most effective tools for those involved in this type of testing, and its myriad benefits will be explained in the following brief. DIC is a non-contact, full-field optical technique used for measuring surface deformation, displacement, and strain. In the context of jet engine testing, DIC can offer several benefits:

- Material Characterization: DIC can help in understanding the behavior of materials used in the engine components under different loading conditions, including thermal and vibrational stresses.

- Structural Integrity Assessment: It allows engineers to monitor and analyze the deformation and strain distribution on the surface of critical components during various testing scenarios, such as thermal cycling, vibration testing, or performance evaluation.

- Fatigue Analysis: By continuously monitoring surface deformation and strain, DIC can aid in fatigue analysis, helping to identify potential failure points or areas of concern over the lifespan of the engine.

- Performance Evaluation: DIC can be used to measure displacements and deformations in real-time during engine operation, providing insights into the dynamic behavior of engine components and their performance under different operating conditions.

- Validation of Computational Models: DIC data can be used to validate computational models used for simulating engine behavior, helping to refine and improve the accuracy of these models.

- Quality Control: DIC can also be employed for quality control during the manufacturing process, ensuring that engine components meet design specifications and tolerances.

Fan blades

Using DIC on engine fan blades can provide valuable insights into their behavior and performance under various conditions. Depending on the testing scenario either a quasi-static or high-speed DIC system can be used, if the engine is operating during the test a high-speed system is required. Here's how DIC can be applied specifically to fan blades:

- Strain Analysis: DIC can measure strain distribution on the surface of fan blades during operation. This data helps engineers understand how the blades deform under different loads, such as centrifugal forces, aerodynamic loads, and thermal stresses. Inconel, the metal alloy used by most manufacturers for fan blades, responds well to standard DIC patterning.

- Vibration Analysis: DIC can detect and quantify blade vibrations, which are crucial for ensuring smooth and stable engine operation. By analyzing vibration patterns, engineers can identify potential resonance frequencies and mitigate risks of fatigue or failure.

- Crack Detection: DIC can detect cracks or damage on the surface of fan blades. By continuously monitoring blade surfaces, DIC can help identify early signs of fatigue or damage, allowing for timely maintenance or replacement.

- Performance Monitoring: DIC can track changes in blade geometry and deformation over time, providing insights into blade performance degradation. By comparing DIC measurements with baseline data, engineers can assess the health and integrity of fan blades throughout their lifespan.

- Material Characterization: DIC can assist in characterizing the mechanical properties of fan blade materials. By subjecting blades to controlled loading conditions and analyzing their response, engineers can validate material models and ensure the reliability of fan blades under extreme operating conditions.

- Safety Assurance: By providing real-time feedback on blade behavior, DIC contributes to the overall safety of jet engines. Early detection of anomalies or deviations from expected performance can help prevent catastrophic failures and ensure the reliability of aircraft propulsion systems.

Overall, applying DIC to jet engines enhances the understanding of their structural integrity, performance, and durability, ultimately contributing to the safety and reliability of aircraft operations.

1 min read

The Impact of Digital Image Correlation in eVTOL Battery Drop Testing

The pioneering 50-foot drop test of an eVTOL battery, a collaboration between Beta Technologies and Wichita State University’s National Institute for...

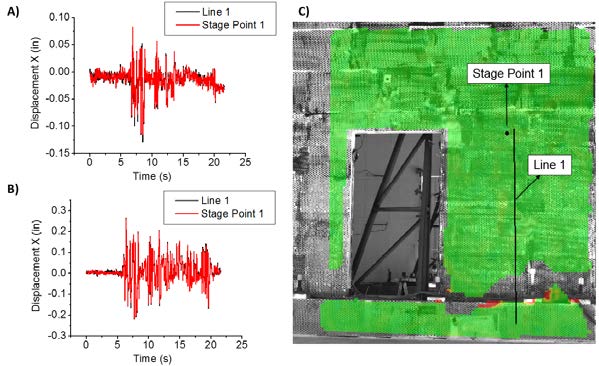

Deformation Measurements During Seismic Loading of Masonry Buildings

ABSTRACT