ZEISS ScanPort: Mobile Scanning Automation at Your Fingertips

{% video_player "embed_player" overrideable=False, type='hsvideo2', hide_playlist=True, viral_sharing=False, embed_button=False, autoplay=True,...

15:36, Feb 24

15:19, Feb 19

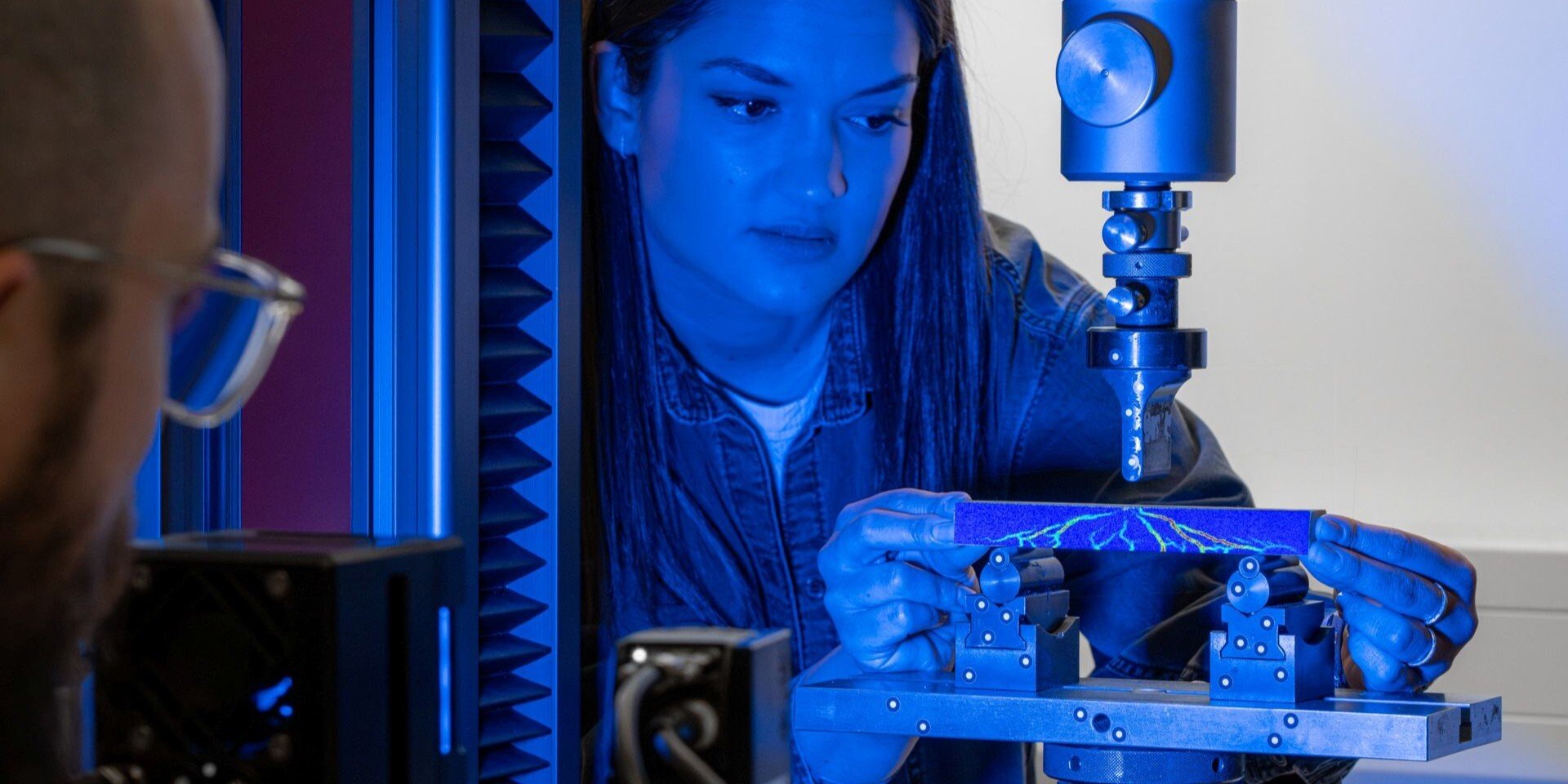

AESUB Blue is an innovative, self-vanishing scanning spray that evaporates in just a few hours, eliminating the need to clean after scanning. Furthermore, AESUB Blue does not contain pigments, which means you avoid the risk of contaminating sensitive areas like laboratories and production sites while greatly increasing efficiency and productivity within digitizing processes.

Features

Features

• Designed for scanning

• Evaporating formula

• Even coating

• Residue free

• Layer thickness ~8-15 µm

• Reference points stick on the coating

• Homogenous and dry to the touch

Applications

• Optical metrology

• Measurement services

• Research and development

• Surface inspection

• Inline scanning

• Process monitoring

• Reverse engineering

AESUB Spray Disappearing Factors

AESUB scanning spray evaporates in less than four hours, varying depending on five factors:

| Temperature | High temperatures shorten the sublimation time | Low temperatures lengthen the sublimation time |

| Airflow | Ventilation will shorten the sublimation time | |

| Surface Structure | An uneven surface will extend the sublimation time. | |

| Layer Thickness | Higher layer thickness will lengthen the sublimation time | |

| Material | Plastics and lighter metals will shorten sublimation time | |

| AESUB Spray Dissolving on Ice Statue | ||

|

Stage 1

|

Stage 2

|

|

|

Stage 3

|

Stage 4

|

|

{% video_player "embed_player" overrideable=False, type='hsvideo2', hide_playlist=True, viral_sharing=False, embed_button=False, autoplay=True,...

{% video_player "embed_player" overrideable=False, type='hsvideo2', hide_playlist=True, viral_sharing=False, embed_button=False, autoplay=True,...

{% video_player "embed_player" overrideable=False, type='hsvideo2', hide_playlist=True, viral_sharing=False, embed_button=False, autoplay=True,...